learn more about Flooring Installation

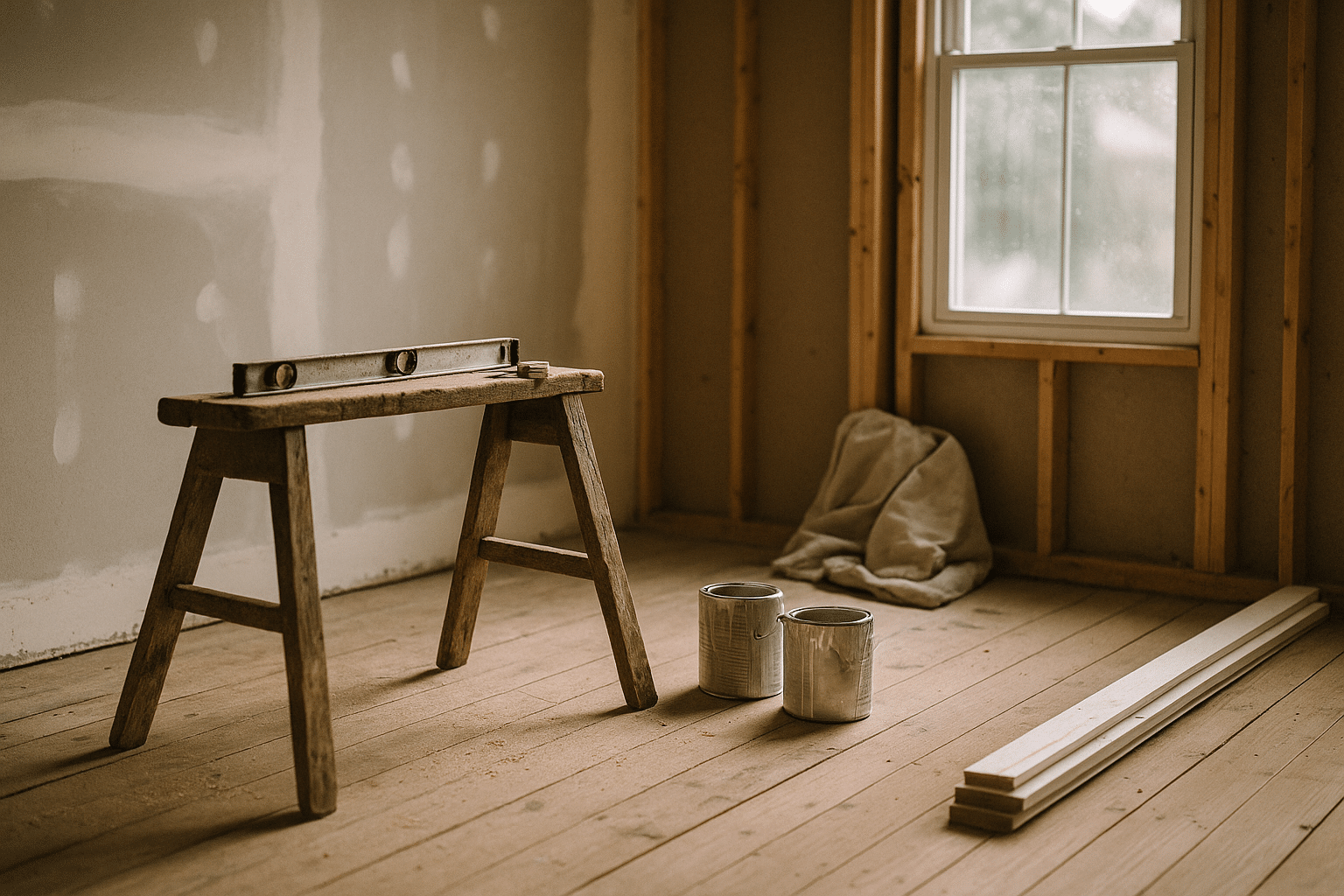

Introduction and Planning: Your Roadmap to a Smooth Flooring Installation

Before a single plank, tile, or roll of carpet touches the floor, a solid plan determines how the project looks, performs, and ages. Think of installation like a road trip: the fastest route is the one with good directions, a tuned vehicle, and a fuel plan. Quick outline of what follows:

– Planning and preparation essentials

– Choosing materials that match lifestyle and budget

– Subfloor and underlayment fundamentals

– Step-by-step workflows by flooring type

– A practical conclusion to move from intention to action

Start with accurate measurements. Sketch your rooms, measure length × width, and add a waste factor to cover cuts and defects. Typical waste allowances are 5–10% for straight-lay patterns and 10–15% for diagonals or rooms with many obstacles. Note door swings, transitions to other floors, and the location of vents. Photograph tricky corners to reference during layout. If you are removing old flooring, estimate disposal volume and plan for safe, dust-minimized demolition. Cover return air vents, and use a vacuum with fine filtration to limit airborne particles.

Moisture and climate control are make-or-break factors. Most wood-based floors prefer indoor relative humidity near 30–50% and temperature around normal living conditions. Solid wood typically performs best when its moisture content is within a few percentage points of the subfloor, minimizing movement once installed. For concrete, run a manufacturer-approved moisture test; common limits for resilient materials often fall in the 75–85% in-situ RH range, while some systems permit higher—always confirm with product documentation. Allow acclimation time for materials per the instructions, which may range from 24 hours for many resilient planks to several days for solid wood.

Gather tools early to avoid halting the job midstream:

– Safety gear: eye protection, dust mask or respirator rated for fine dust, hearing protection, knee pads

– Layout tools: straightedge, chalk line, square, spacers, non-marking pencil

– Cutting tools: appropriate saws or cutters for wood, vinyl, or tile; fresh blades are essential

– Installation tools: tapping block, pull bar, trowels with the specified notch size, rollers where required

Finally, decide on DIY versus professional help. A single room with floating planks might be a weekend task for a prepared DIYer, while intricate tile patterns or glue-down hardwood often benefit from a seasoned pro. Time estimates help set expectations: a typical 200–300 sq ft room can take a day for floating floors after prep, two days or more for tile (including setting and grout cure), and variable time for site-finished wood due to sanding and finish drying. With a plan in place, you lower risk, keep costs predictable, and set yourself up for a flooring upgrade that looks intentional and feels sturdy underfoot.

Choosing the Right Material: Comparing Wood, Resilient, Tile, and Carpet

Flooring materials differ in feel, durability, moisture tolerance, cost, and maintenance. Matching your space to the right category yields a floor that looks good longer and performs with fewer surprises. Here’s a practical comparison that balances real-world use with budget awareness:

Solid and engineered wood:

– Look and feel: warm, timeless, refinished multiple times (solid) or at least once (many engineered products)

– Installation: nail-down or glue-down; some engineered options float

– Moisture: sensitive; surface spills are manageable, standing water is risky

– Cost: material often mid-to-high; installation is skilled work

– Lifespan: decades with proper care; refinishing extends service

Laminate:

– Look and feel: convincing wood visuals, firm underfoot, resistant to surface scratches

– Installation: usually floating with click joints; DIY-friendly

– Moisture: improved resistance in many lines, but prolonged water exposure can lead to swelling

– Cost: typically budget-friendly with wide style options

– Lifespan: moderate; protect joints from moisture and control humidity

Luxury vinyl plank and tile:

– Look and feel: realistic textures, resilient and quiet; comfortable in kitchens and basements

– Installation: floating or glue-down; requires flat subfloors

– Moisture: highly tolerant; suitable for bathrooms and below-grade spaces

– Cost: moderate; labor varies by method

– Lifespan: substantial in normal residential use; easy to repair by plank replacement

Porcelain and ceramic tile:

– Look and feel: crisp lines, endless designs, ideal for wet zones

– Installation: thin-set and grout; substrate must be flat and stable

– Moisture: excellent resistance; ideal for showers and entries

– Cost: material ranges widely; labor is detail-intensive

– Lifespan: long; grout maintenance and movement joints are key

Carpet:

– Look and feel: warm, soft, sound-dampening; great in bedrooms

– Installation: stretch-in with pad or direct glue-down

– Moisture: vulnerable; reserve for dry spaces

– Cost: broad spectrum; padding quality affects comfort and longevity

– Lifespan: varies by fiber and traffic; regular cleaning sustains appearance

Thermal comfort and acoustics matter, too. Dense underlayment under floating floors improves impact sound in multi-level homes, and many buildings target IIC/STC ratings of 50 or higher for peace between floors. For radiant heat, verify compatibility; many engineered wood and resilient products perform well if surface temperature stays within manufacturer limits (commonly around 27°C/80°F). Sustainability considerations include certified, responsibly sourced wood and low-VOC adhesives or finishes. Balance how you live—pets, spills, heavy furniture, quiet mornings—against installation complexity and long-term care. The material that aligns with your daily routines generally delivers the most satisfaction per dollar.

Subfloor and Underlayment: Flat, Dry, and Ready for a Lasting Finish

The subfloor and underlayment are the unsung layers that make finished flooring look and feel right. Their job is to keep surfaces flat, stable, dry, and acoustically comfortable, which protects both appearance and structure. Begin with a diagnostic scan: walk the room, note squeaks, check for spongy spots, and place a long straightedge or level to reveal dips and humps. Many floating wood-look floors specify flatness around 3/16 inch over 10 feet, while larger-format tile often requires tighter tolerances, as little as 1/8 inch over 10 feet, to prevent lippage. Mark out corrections with painter’s tape.

Common subfloors include plywood or OSB over joists and concrete slabs. On wood subfloors, secure loose panels with screws to eliminate squeaks, then sand high seams and fill low areas with a flooring-approved patch compound. On concrete, remove weak surface material, grind high spots, and use a self-leveling underlayment where needed, following primer instructions and minimum thicknesses. Moisture testing is critical: in-situ RH or other approved methods help verify conditions for adhesives and moisture-sensitive products. If readings exceed limits, mitigation options include liquid-applied vapor barriers or switching to a floating assembly with a vapor retarder where allowed by the product’s specifications.

Underlayments do specific jobs:

– Vapor retarders: help reduce moisture vapor from slabs or crawlspaces (e.g., 6-mil poly under many floating laminates/vinyl on concrete; specialized membranes for wood floors)

– Acoustic layers: reduce impact sound and footfall noise; look for products with tested IIC/STC data appropriate for your building

– Cushion and support: carpet pad density influences comfort and longevity; too soft may cause premature wear

– Crack isolation and uncoupling membranes for tile: help manage minor substrate movement and reduce the risk of cracks telegraphing to the surface

Expansion and movement are part of life for floors. Leave perimeter gaps—often about 1/4 inch for floating floors—around walls and fixed objects, and plan transitions in long runs or between rooms to prevent buckling. For tile, incorporate movement joints at perimeters and at intervals in large spaces per industry guidelines, especially in areas with strong sunlight or temperature swings. With radiant heat, bring temperatures up and down gradually and observe the manufacturer’s maximum surface temperature to avoid stress-related issues.

The quality of what you do under the finished material strongly predicts how that floor will perform after installation. Flatness yields tight joints and smooth lines; dryness protects adhesives and organic materials; acoustics make a home feel calm; and properly planned movement joints prevent cracks or peaks. Invest the time here, and the visible layer rewards you with cleaner lines and longer service life.

Installation Workflows by Floor Type: Step-by-Step Methods That Deliver Results

Every flooring type has a rhythm. Following the right sequence with the right tools turns a box of materials into a cohesive surface. Below are practical workflows for common categories, including layout tips that save time and reduce waste.

Floating laminate and luxury vinyl plank:

– Prep: verify flatness and moisture; install underlayment per instructions

– Layout: orient planks toward the longest wall or main light source; calculate starter strip width to avoid slivers on the final row

– Install: use spacers at walls; angle and click planks together; employ a tapping block and pull bar to snug joints without damaging edges

– Stagger: offset end joints by at least 6 inches; avoid H-patterns or stair-steps

– Cuts: undercut door jambs for a clean look and to maintain expansion space

– Finish: install transitions and baseboards; remove spacers; keep perimeter gaps clear of debris

Nail-down or glue-down wood:

– Acclimate: confirm moisture content and environmental conditions are within target

– Layout: snap a control line parallel to the longest straight reference; dry-fit the first few rows

– Nail-down: fasten at the recommended spacing (often 6–8 inches along each board), keeping fasteners from tongues and ends

– Glue-down: trowel the specified adhesive with the correct notch; roll or weight sections as directed for bond integrity

– Details: stagger end joints; maintain expansion gaps; sort boards for color and grain variation to achieve a natural blend

Porcelain and ceramic tile:

– Substrate: ensure flatness; install crack-isolation or uncoupling membrane if required

– Layout: find the room’s center; dry-lay to balance cuts at walls and avoid narrow slivers

– Setting: select trowel notch size to achieve adequate coverage; back-butter large-format tiles; periodically lift a tile to confirm coverage

– Grouting: respect cure time before grouting; pack joints fully; clean in stages to avoid haze

– Movement: leave gaps at perimeters and around penetrations; use flexible sealants where appropriate

Carpet (stretch-in):

– Prep: install tack strips with the correct gully; lay pad and tape seams flat

– Seams: align pile direction; seam with heat or appropriate tape; roll to set

– Stretch: use a power stretcher to tension carpet wall-to-wall; trim and tuck at perimeters

– Finish: set transitions; vacuum thoroughly; check for pattern alignment

Time management matters. For a typical room, plan a half day for prep and layout, a day for floating plank install, two days for tile plus grouting and initial cure, and more for site-finished wood due to sanding and finish schedules. Always protect fresh installs from heavy furniture until adhesives or finishes have cured—24 to 72 hours is common, but follow product guidance. When in doubt, a small test area validates your method before you commit across the room.

Conclusion: From Planning to Finish—Installing Floors with Confidence

Good flooring installs don’t happen by accident; they are the result of careful prep, material choices that fit your lifestyle, and steady, methodical work. By measuring accurately, controlling moisture, flattening the substrate, and respecting expansion, you prevent the most common failures before they start. Choose materials with eyes open: wood for warmth and long-term value, resilient for water-prone spaces and quick comfort, tile for enduring surfaces, and carpet for quiet and softness where spills are unlikely.

If you are mapping your next steps, use this practical checklist:

– Confirm room measurements and add the appropriate waste factor

– Document moisture and flatness; correct issues before opening boxes

– Verify material compatibility with existing conditions (slab, radiant heat, condo sound rules)

– Assemble safety gear and the specific tools your method requires

– Dry-fit layouts to avoid narrow cuts and awkward transitions

– Respect cure times before moving in furniture or area rugs

Maintenance is the quiet partner of a long-lived floor. For wood and laminate, control indoor humidity and use felt pads under furniture. For resilient surfaces, avoid harsh solvents and keep abrasive grit at bay with entry mats. For tile, a neutral pH cleaner preserves grout; reseal cementitious grout as recommended. For carpet, regular vacuuming and prompt spot treatment keep fibers looking fresh. Troubleshoot early: slight cupping in wood hints at moisture imbalance, peaking in floating floors often signals insufficient expansion space, hollow sounds under tile may indicate poor coverage, and ripples in carpet point to insufficient stretch.

Whether you hire a pro or do it yourself, a thoughtful plan transforms installation from a stressful chore into a satisfying project. You’ll walk a little slower across a room you finished yourself, admiring straight lines, quiet seams, and a surface that feels right underfoot. With the guidance above, you can move from inspiration to installation—and enjoy floors that look composed on day one and dependable for years to come.