Introduction to Mini Excavators

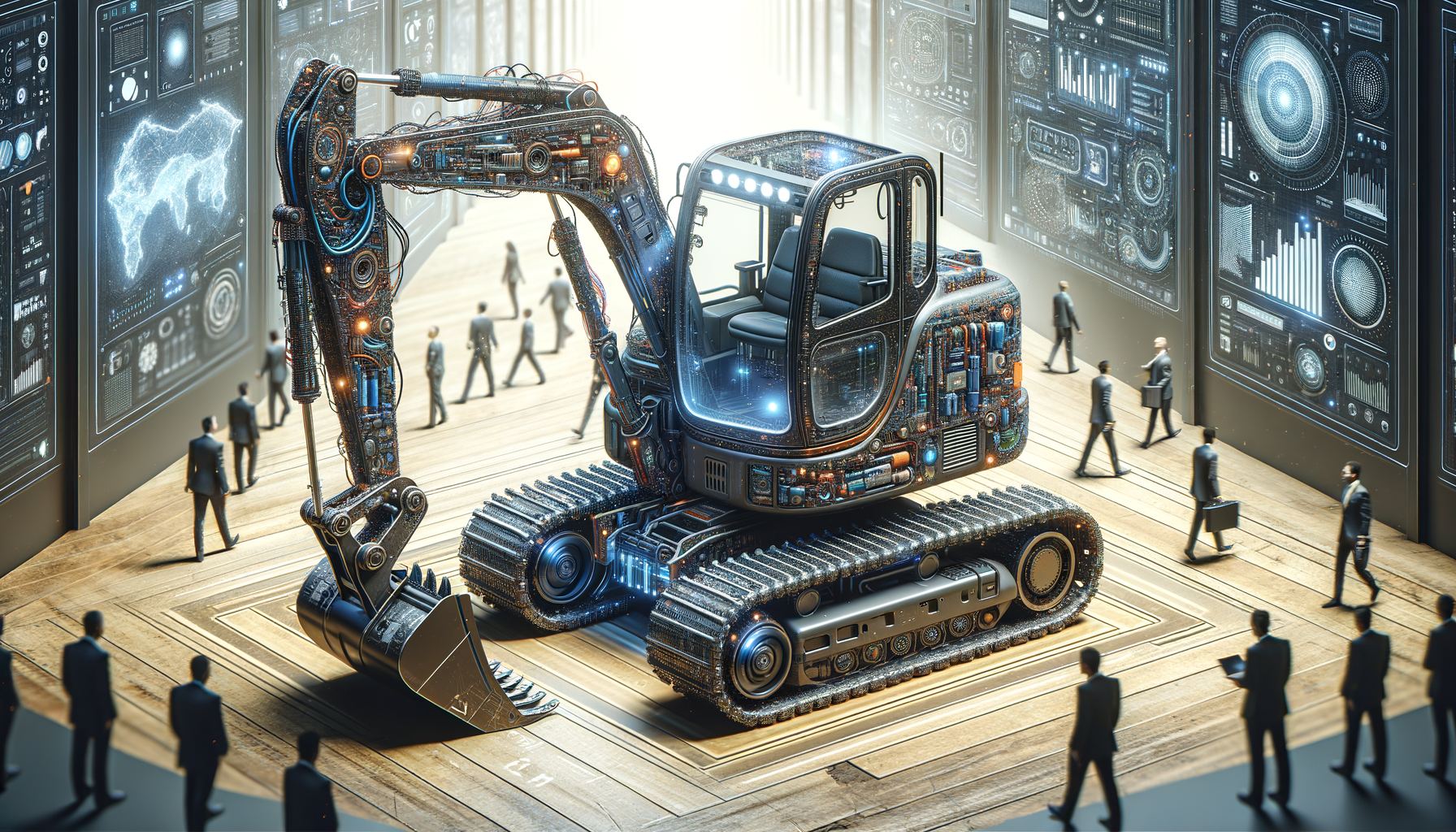

Mini excavators have become indispensable tools in the construction and landscaping industries. Their compact size, coupled with impressive power and versatility, makes them ideal for a variety of tasks. These machines excel in areas where larger equipment cannot maneuver, offering a practical solution for projects with space constraints. As we look towards 2025, understanding the evolving features and capabilities of mini excavators is crucial for making informed purchasing decisions.

Mini excavators are primarily used for digging, trenching, and site preparation. Their ability to operate in tight spaces without compromising on functionality makes them a preferred choice for many contractors and project managers. Additionally, these machines are often more cost-effective compared to their larger counterparts, both in terms of initial purchase price and ongoing operational costs.

In this guide, we will explore the key aspects of mini excavators, including their features, applications, and maintenance requirements. By understanding these elements, you can better assess which model aligns with your specific needs and project conditions.

Key Features of Mini Excavators

Mini excavators come equipped with a range of features that enhance their utility and efficiency. One of the most notable attributes is their compact design, which allows them to navigate confined spaces with ease. This makes them particularly useful in urban construction sites and residential landscaping projects.

Another significant feature is the advanced hydraulic system found in many modern mini excavators. This system provides smooth and precise control, enabling operators to perform tasks with greater accuracy. Additionally, many mini excavators now come with quick-attach systems, allowing for rapid switching between different attachments such as buckets, augers, and breakers.

Some models offer zero or minimal tail swing, which reduces the risk of damage when working close to structures or other obstacles. Furthermore, advancements in technology have led to the integration of telematics systems, providing real-time data on machine performance and maintenance needs. This not only helps in optimizing operations but also extends the lifespan of the equipment.

Typical Applications of Mini Excavators

Mini excavators are versatile machines that can be employed in a wide range of applications. In construction, they are commonly used for digging foundations, trenching for utility lines, and site leveling. Their ability to perform precise operations makes them suitable for tasks that require meticulous attention to detail.

In the landscaping sector, mini excavators are invaluable for tasks such as grading, planting, and removing debris. Their compact size allows them to work in gardens and yards without causing excessive disruption to the surrounding environment. Additionally, they are often used in agricultural settings for tasks like irrigation trenching and land clearing.

Utility companies also rely on mini excavators for maintenance and installation of pipelines and cables. The machines’ ability to maneuver in restricted spaces, such as alleyways or between buildings, makes them ideal for urban infrastructure projects. Overall, the adaptability of mini excavators across different industries underscores their importance in modern project execution.

Operational Considerations and Maintenance

Operating a mini excavator efficiently requires understanding its capabilities and limitations. Proper training for operators is essential to ensure safety and maximize productivity. Familiarity with the controls and features of the specific model in use can significantly enhance operational efficiency.

Regular maintenance is crucial to keep mini excavators in optimal condition. This includes routine checks of hydraulic systems, engine components, and tracks or wheels. Scheduled servicing, as per the manufacturer’s guidelines, helps prevent breakdowns and extends the machine’s lifespan. It is also important to use the correct attachments and ensure they are properly secured to avoid operational hazards.

Another consideration is the environmental impact of mini excavators. Many manufacturers are now focusing on reducing emissions and improving fuel efficiency, aligning with global sustainability goals. Choosing a model with eco-friendly features can contribute to environmental conservation efforts while also potentially reducing operational costs.

Conclusion: Making the Right Choice

Choosing the right mini excavator involves evaluating several factors, including the specific requirements of your projects, the machine’s features, and its operational costs. By understanding the diverse applications and capabilities of mini excavators, you can select a model that best suits your needs.

As the industry continues to evolve, staying informed about the latest technological advancements and market trends is essential. Whether you are a contractor, property owner, or project manager, investing in a mini excavator that aligns with your operational goals can enhance productivity and efficiency.

Ultimately, a well-chosen mini excavator not only meets the demands of current projects but also offers flexibility for future endeavors, making it a valuable addition to any equipment fleet.

Leave a Reply